Modern supply chain planning is a complex and dynamic process that involves the coordination and integration of multiple stakeholders, including suppliers, manufacturers, distributors, and customers, in order to deliver products and services to the end consumer. It encompasses all aspects of the product lifecycle, from sourcing and procurement to production, logistics, and delivery.

Just like the entire semiconductor and high-tech industries, Nvidia faced tremendous supply chain challenges in the past few years. We’ve seen large volatilities in demand. COVID-19 lockdowns brought a surge in demand for Nvidia products due to the shift to remote work and online learning. At the same time travel restrictions and factory closures caused delays in production and shortages of critical parts. Trade disputes and tariffs, e.g., between the US and China have led to increased costs and disruptions to the supply chain.

Having to tackle all these challenges simultaneously the past few years required us to adopt new models, technologies and algorithms to help us sustain our rapid revenue and profit growth. We believe we needed the following three elements in our solutions.

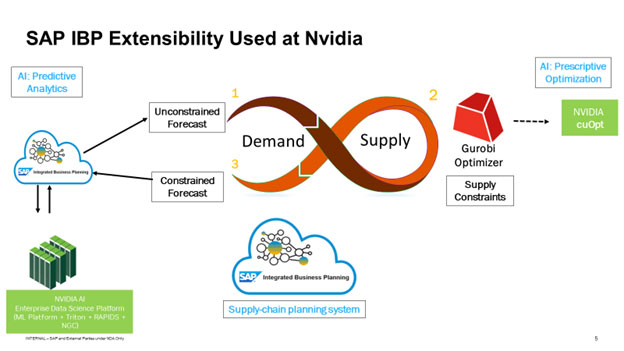

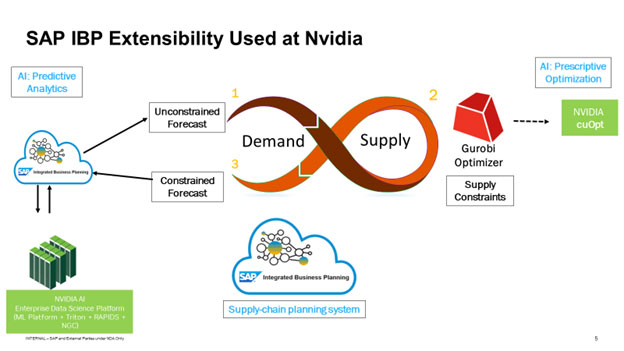

At the core is a Supply Chain Planning (SCP) system which is an integrated demand and supply planning system that enables consolidation of data from different sources to create a unified holistic view. Complementing the SCP would be predictive analytics models leveraging traditional statistics and AI/ML that will be able to handle high fluctuations in demand and understand the complexity from multiple demand indicators. Finally prescriptive optimization models leveraging operations research algorithms are needed to incorporate material and capacity constraints into the supply chain plans.

We began our journey by modernizing our Forecasting system first. After an extensive evaluation of multiple tools, we selected SAP IBP. SAP IBP is a cloud-based solution, offering flexibility, scalability, and easy accessibility. IBP integrates seamlessly with other SAP solutions, such as SAP ERP, BW and APO, enabling a unified planning process. Our planners need options on UI and only IBP offers both a web-based UI along with Excel add-ins.

It took us 9 months to implement IBP Demand Planning for our consumer business units and another 9 months for our enterprise business units. We now have a total of 250+ users spread across the globe. We had moved 12+ separate Excel models for the different Nvidia business units into IBP resulting in more consistent and improving forecast results. We estimate about 10K+ hours of productivity savings per year for our planners. Cycle time from sell through forecast to revenue target setting has been reduced from 8 days to 4 days.

SAP IBP offers advanced analytics and scenario modeling capabilities that we use for our simpler use cases. But some of our use cases require more advanced AI/ML models such as sell through forecasting of our desktop and notebook business units.

Artificial intelligence (AI) has been seen as a game changer in supply chain planning specifically areas covering demand forecasting, inventory optimization, route optimization and risk management. In NVIDIA’s case there are two main areas AI can greatly help, these are predictive analytics and prescriptive optimization.

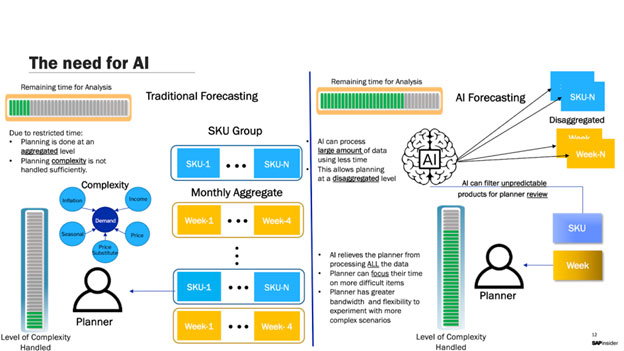

Traditional forecast algorithms do not have the capacity and flexibility to consume large and diverse data to understand the complex relationships of different factors to generate a more accurate forecast. They are also very rigid in terms of their adaptability to handle changing trends or unexpected events. This is due to their inherent ability to incorporate external factors that can significantly help in creating a richer forecasting model. But perhaps the most significant downside of using traditional forecasting methods is that they are often time consuming and labor-intensive, thus making them more prone to human error. This problem becomes compounded when the planner is handling tons of data. The planner requires significant manual effort to gather and analyze data and in between may result in incorrect data entry or assumptions.

Not only can AI-based forecasting handle more complex data, it’s also very adaptive, can process large amounts of data much faster and reduces the human factor. AI-forecasting models can learn from past data and adapt to new information in real-time, making them more accurate and flexible in their predictions. They can also adjust their models based on changing trends, which allows them to provide more accurate forecasts. Moreover, since AI is mostly based on deep learning models which can leverage high-performance computers like graphical processing units (GPUs), it can process large amounts of data in parallel. Finally, since most of the manual process are fully automated it reduces risk of human error.

Let’s walk through an example of how we use SAP IBP extensibility for Forecasting.

At Nvidia our consensus forecast is our key data element that drives both our revenue forecast w/ Wall Street as well as our build plans. As you can see in the diagram below, the first step in our forecasting process is generating an unconstrained consensus forecast within SAP IBP plus external advanced AI/ML models in Nvidia Kratos processing historical data, various demand factors and planner judgment.

In the second step we run mixed integer programming models to generate supply constraints against the unconstrained forecast. We run the model in a custom Gurobi solver we built internally. We are currently migrating the solution to our own Nvidia Cuopt optimization product that leverages CUDA for parallel GPU processing at lightning speeds

In the third and last step, we generate our constrained forecast that will be the basis of our revenue forecast and build plans

Due to the interconnectedness of global trade coupled with the rise of e-commerce, a company’s supply chain must adopt to the challenges of global disruptions (Covid, tariffs) and satisfying increased demand with supply constraints. As we have discussed, SAP IBP plus external models like Gurobi and Nvidia AI (Kratos) can meet the scale and complexity of these challenges.